In measuring the amount of liquid or gas or vapor that passes through a pipeline, the flow meter is the device that you needed. There are kinds of flow meters that measure the amount of fluid or gas during a set time. Like for example, the flow meter counts 100 liters per minute. Also, there are flow meters that measure the totalized amount of fluid that passes through the flow meter. Just for instance, within the total passes, it has 10000 liters.

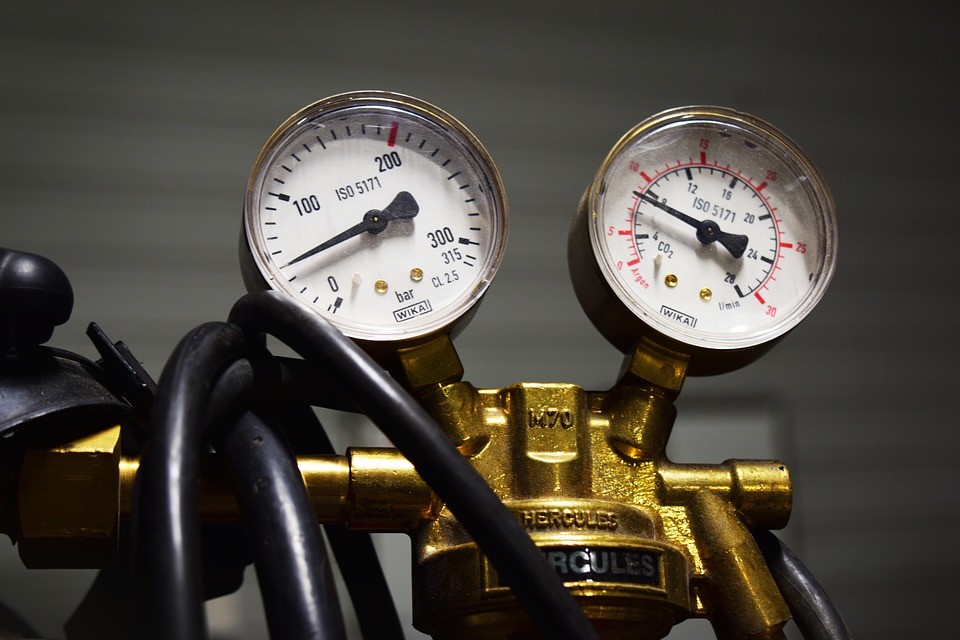

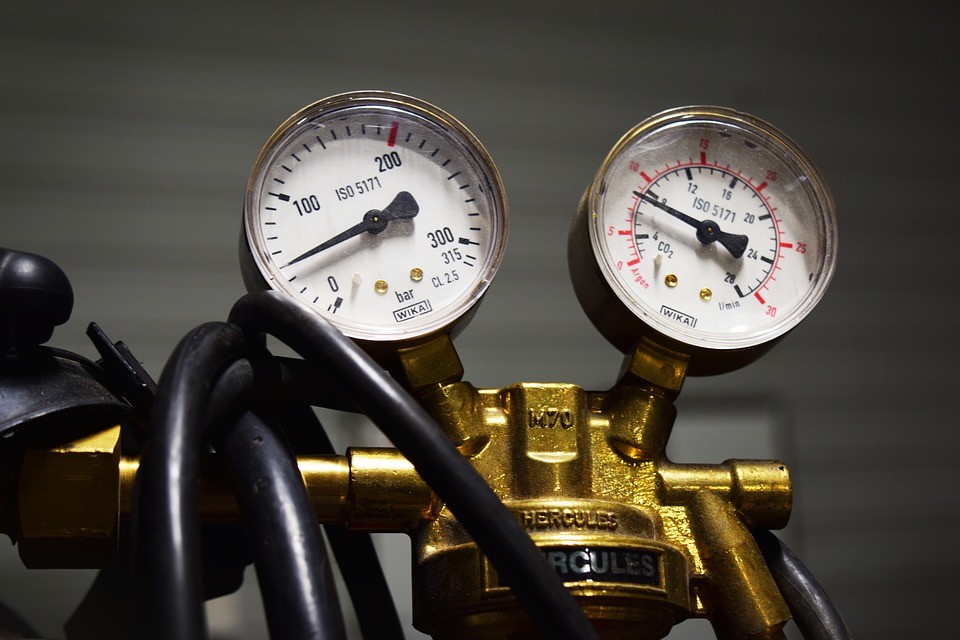

Mainly, the flow meter consists of a primary device, transducer, and transmitter. The transducer could sense the fluid that passes through the primary device while the transmitter produces a good flow signal. This signal comes from the raw transducer signal. Often, these two component are joined together. So that means that the flow meter may be one or more physical devices.

Getting to know how it works and how to use it will likely extend the life span of your flow meter. Taking care of the equipment is helpful for the water process system operation and the user itself. Understanding the function and the application also lessens your time in maneuvering it. Be guided and be reminded of the following:

Cautions upon the installing area of flow meters

Regarding the pipping and the area in which the flow meter will be located, this is what you most important you need to consider: for the pipping, the direction is avoided to be downward flow in the liquid application including also, together with the size, schedule, materials, accessibility, regulators, flange-pressure rating, valves, and available straight-pipe run lengths.

Whoever the engineer who has taken over the work field, he or she must know if magnetic fields or vibration is present or possible in the area. The engineer also needs to identify if the pneumatic or electric power is available. He or she needs to determine if the city is known for explosion hazards or if there are other special needs to follow up such as compliance with sanitary regulations.

Cautions within the installation of flow meters

Despite flow meter measure liquid or gas, the installation cautions for these are similar. Within the liquid service, secure that the flow meter is installed correctly in such a way that it remains full of liquid. It is because the gas or vapor in the flow meter can adjust its geometry. Also, in return, it negatively affects the accuracy of its measurement. In the gas or vapor service, just as stated, secure the proper installation then make sure to remain the gas entirely. It is because it can affect the accuracy of its measurement. During these times, one mistake can cause issues with the pump. Should this happen, Industrial Pump Repair Services may need to be contacted in order to get things fixed and working as they should again.

Disturbances located upstream or downstream, sometimes, of the flow meter like the pipe elbow and control valves, effects on getting an accurate measurement. It is because the flow meter may not be able to measure because of the disturbed flow streams accurately. Locating the control valves downstream of the flow meter is needed. By such, the flow disturbances are not introduced directly towards the flow meter. Once the downstream and upstream piping was designed correctly, it can remove troubles which are the most significant effect in the accurate measurement.

Cautions within the application of flow meters

There are a constraint and specific instruction which needs to be followed in each type of flow meter. No one fits all flow meter’s direction. In selecting the right flow meter, use the application as your guide. Do not settle for technology. There are plenty of these technologies that all worked well on many forms. Once you have started using an application, then you can select the technology that you have wished to use based on accuracy, durability, reliability, and cost.

Maintaining the flow meter

There are numerous factors which could affect the life expectancy of flow meters. And thus, there are several maintenance requirements on it. Above all the reasons that may change the life of the flow meter, the primary factor on it is matching the right instrument to a specific application. The poor selection of devices may cause problems at an early date. The flow meters with no moving parts commonly require less attention rather than units that have moving parts. However, all flow meters may eventually need and require kind of maintenance for its better operation.

Takeaway

Commonly, the mistake on flow measurements is the reversal of the sequence. Just like for example instead of selecting a sensor which is properly performing, the exhibitor attempt to use a less expensive device. These cheap ones that were purchased could be the reason for most costly installations. Thus, it also affects the performance of the operation within the system. Reading the discussion will surely give a benefit towards you for broadening your understanding towards flow meters. Consider these various stages so that you could enjoy the bonus at the same time.