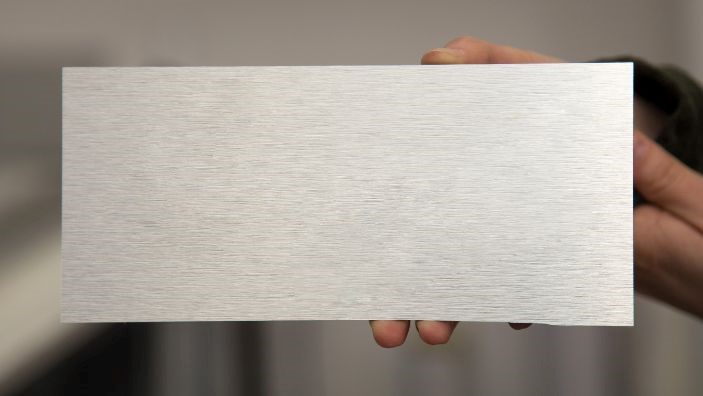

In the world of manufacturing, selecting the right raw materials is crucial for the success of your projects. One versatile and efficient option is aluminum blanks. These pre-cut, flat pieces of aluminum offer numerous benefits that can streamline your manufacturing process, reduce costs, and enhance product quality. Read on and discover the advantages of using aluminum blanks in manufacturing.

Minimized Waste

One of the primary benefits of using aluminum blanks is the reduction of material waste. Since they come pre-cut to specific dimensions, they leave less excess material to trim or discard during the manufacturing process. This efficiency not only conserves resources but also helps reduce overall production costs.

Consistent Quality

Purchasing aluminum blanks from a reputable supplier ensures that you receive materials of consistent quality. Manufacturers ensure these blanks adhere to tight tolerances, ensuring dimensional accuracy and uniformity across your production runs. This consistency can lead to improved product performance and customer satisfaction.

Reduced Machining Time

Aluminum blanks are ready to use, saving time and labor that you would otherwise spend cutting raw materials into the desired shape. Since they streamline this initial step, they allow you to significantly reduce production time, allowing your team to focus on other crucial aspects of the manufacturing process.

Cost Savings

Using aluminum blanks can result in cost savings for your manufacturing operation. By reducing material waste, labor, and machining time, you can minimize overall production expenses. Additionally, aluminum is known for its excellent strength-to-weight ratio, offering the durability and performance of heavier metals without the added cost.

Versatility

Aluminum blanks are available in a range of grades and alloys, allowing you to select the ideal material for your specific application. Whether you require corrosion resistance, high strength, or superior formability, you can find an aluminum blank to suit your needs.

Now that you know the advantages of using aluminum blanks in manufacturing, make sure you know the different grades of aluminum blanks so that you have the best sense of how to enhance your processes.